About Us

With 45 years' experience, Marmon Renew is a global leader in beverage and foodservice equipment remanufacturing. Our commitment to quality, ability to meet specific customer needs, and provide 'like new' equipment at a reduced cost provides an immediate value proposition to our customers.

As equipment experiences wear and tear, downtime and maintenance costs can increase. Our team of experts specialize in enhancing, modifying and revitalizing your equipment, bringing it back to 'like new' condition for a fraction of the cost.

Taking Old, and Making It Look and Perform Like New. We take pride in our ability to increase the life of your equipment. Our proprietary process starts with “Reverse Manufacturing” which delivers a like new piece of equipment, maximizing your investment.

With more than 40 years of remanufacturing experience, our capabilities span working with national OEM manufacturers across multiple product lines. Our warehouse and logistics specialists provide flexibility to your equipment utilization requirements. Our commitment to quality helps reduce spending on service calls and downtime of equipment.

We work with you to understand your specific needs and how to provide you with a customized solution. We can also work with different levels of your organization to gain the necessary knowledge to solve issues and enhance profitability.

Customers are our first Priority

From our Customers

Our Approach Is Different

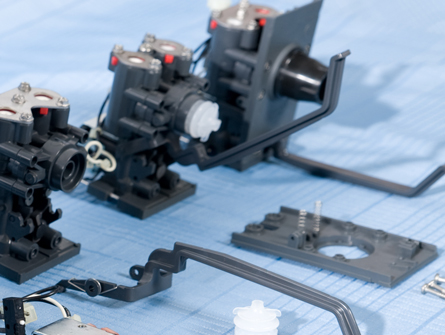

During the remanufacturing process, units are disassembled into their individual parts. Trained technicians then inspect each part for defects, damage and cosmetic appearance. Upon passing inspection, the parts are staged and processed accordingly. We only use OEM parts.

Traditional refurbishing companies typically perform only the least amount of services required to allow a product's return to market. In many cases, products are merely cleaned and shined, then is placed back in the field.

Have Any Questions?

Who We Serve

© 2026 Marmon Renew. All rights reserved. Our terms and conditions.

Made by the Drioduo